E-Waste Management: A Long Road Ahead

Technology is definitely here to stay, and most of us cannot live without our electronic gadgets. In fact, most Australian households own more than one electronic gadget and other electric appliances at any one time.

Because Australia is one of the biggest consumers of electronics, we are also one of the bigger contributors of e-waste. Globally, about 50 million tonnes of e-waste is produced every year, with 600,000 tonnes generated in this country.

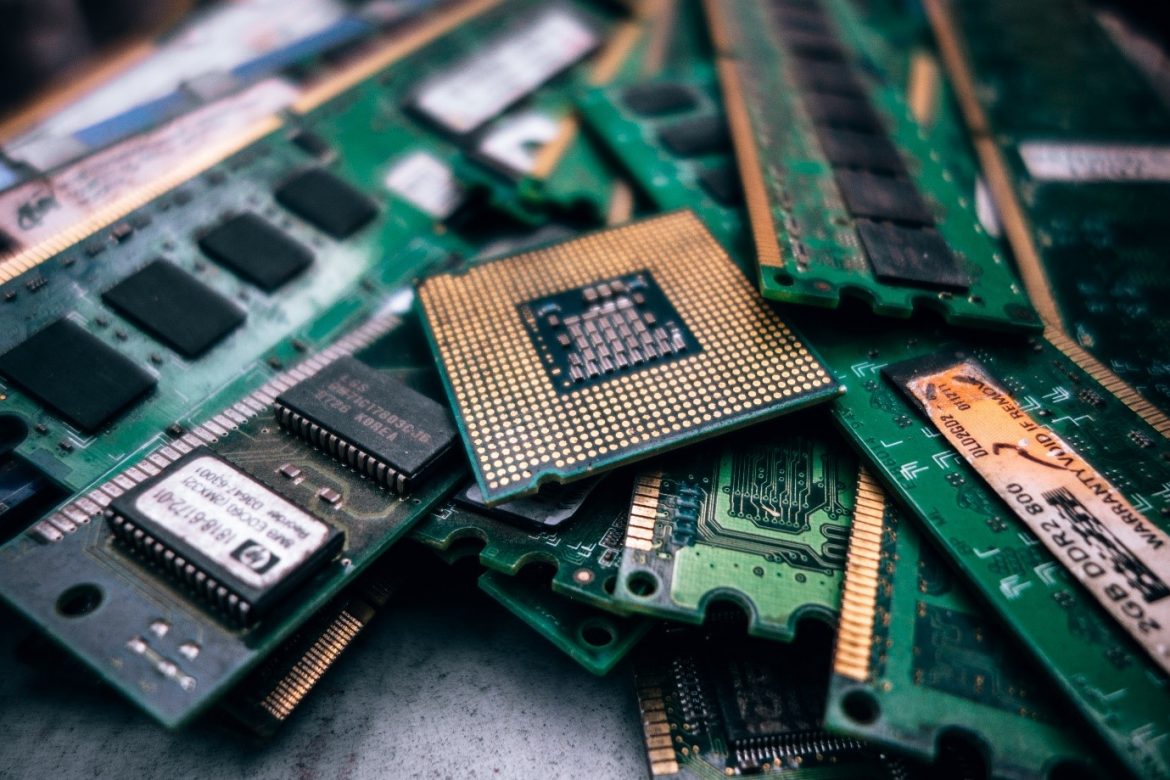

E-waste refers to any discarded electronics that are no longer useful or functional, and this includes phones, televisions, computers and laptops. E-waste is generated three times faster than all other forms of waste due to its shorter shelf life and the quick change in technology.

Most e-waste ends up in the landfill, where it can become grave environmental and public health hazard because they contain pollutants such as lead, mercury and arsenic.

E-waste management and its challenges

Recycling is a good way to help prevent these pollutants from ending up in landfill, while also recovering valuable metals in electronics that can be reused. Unfortunately, this is an expensive process to invest in, which serves to discourage businesses from actively partaking in it.

Although industries such as IT, manufacturing, transport, health and education are typically considered to be the largest producers of e-waste, the fact is that any industry that requires electronics for its operations would contribute to e-waste production.

As we become increasingly reliant on technology, there is a growing demand for e-waste management processes and equipment that are simplified and cost-effective.

Despite the need for extensive e-waste management processes, challenges exist. One of the greatest hurdles faced by this industry is the legislation pertaining to it. A number of key pieces of legislation have been introduced in recent years, and these without a doubt have resulted in an overall increase in recycling. However, the industry is still plagued by the narrow definition of e-waste, a lack of clarity over the role of stakeholders as well as weak auditing and compliance measures.

Investing in sustainable e-waste management processes

Although rules and regulations around e-waste management are still a work in progress, businesses can and should be proactive in taking steps to tackle this issue, starting by adopting sustainable e-waste management processes.

Genox, one of the largest manufacturers in this industry, is committed to developing cost-effective solutions for e-waste recycling and heavily invests in research and development. Our extensive range of e-waste management equipment includes shear shredders, vertical crushers, heavy duty granulators and air separation systems.

We can also develop equipment that’s tailored to suit specific business requirements, to provide a reliable and cost-effective solution for your needs.

Applied Machinery are the exclusive distributors of Genox recycling machinery in Australia, and they maintain a constant inventory of machines in stock here in Melbourne for quick delivery across the nation. They provide turnkey solutions for all of their equipment including installation and of training, to ensure customers are able to get maximum benefits from all of their Genox equipment.

To find out more about the latest product innovations in e-waste management or customised solutions for your business, please contact us at (03) 8710 8100 or email sales@genoxmachinery.com.au